| Home | About us | Lace Braiding | High Speed Braider | Impressum |

|

|

english |

>>Download product catalogue |

|||

|

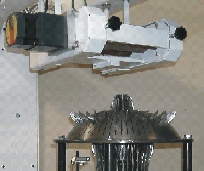

Solenoid

The concept of a successful machine Beater drive and beater A beater that operates exactly and without any play is fundamental to the production of high quality bobbin-lace. The beater is driven by a cylindrical flanged eccentric. The exact engagement of the cam by pairs of adjustable rollers at the top and bottom of the flange ensures precise blade guidance without any play. The difficult task of synchronizing the open and closed sets of blades is eliminated. Automatic shot down triggered by thread breaks or empty bobbins and overload safety clutch The shutdown device scans each individual carrier and stops the machine by means of limit switches as soon as a thread breaks or a bobbin runs out of thread. If the gear ring in the carrier drive becomes stiff of jams, a safety clutch immediately disengages the drive from the gear ring and prevents any material damage.

Pattern control

The pattern control is specially developed for lace braiding machines. It ensures reliable and efficient operation. The maintenance is very easy and no specialist knowledge of electronics is necessary. Every SKZ 8 has a control-terminal on eye-level with a convenient eprom-socket and a display with a simple keypad. The terminal fulfils two functions:

Special auxiliaries

The design monitor verifies the correct execution of each design section. In case of deviation from the design, the machine is immediately stopped and the location of a fault is shown on the display. This entirely rules out the production of flawed fabric. A bobbin lace separator can optionally be installed between the take-off and the container for the finished bobbin lace. It heats and destroys the separating thread between the braids and thus obviates the need for manual intervention. The heater is shut down when the machine is stationary to avoid damaging the fabric.

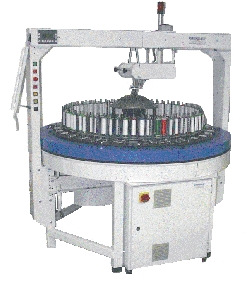

machine sizes: 44 to 96 carriers (others available on request) 55 mm standard pitch for flanged bobbins with 45 mm diameter and 122 mm overall length dimensions (depending on the number of carriers): height 1660 to 1750 mm, width / depth 1500 to 2450 mm weight (depending on the number of carriers): 500 to 1080 kg power consumption (depending on the number of carriers): 0,55 to 1,1 kW

|

|||||

|

Lace Braiding Machine

Model SKZ 8 with electronic pattern control Industrially produced bobbin laces are exact replicas of those crafted by hand. This attribute and the availability of a wide varity of yarns, including cotton, linen, acrylic, blended, synthetic continuous filament and metallic, distinguish bobbin lace from other types and substantiate its value as a commodity and durable product. Classic applications for bobbin lace as a value enhancing appliqué or backing material:

For production reasons, industrial bobbin laces are made in the form of tubular fabric or braid. The fabric width depends on the following:

The final and exact width of the bobbin lace derives from these factors and the selected diameter of the lace collector and mandrel, on which the fabric is processed and taken off. An infinite variety of patterns can be created. Krenzler offers specialist advice on selecting patterns and an efficient pattern service for those who lack the expertise required to process the pattern documentation (pattern draft and set-up instructions). Customers that use this service submit designs of the bobbin laces they wish to produce and the design service department compiles the appropriate documents immediately.

Bobbin Lace

a high-quality industrial product This new generation of machines is founded on knowledge accumulated since 1862, our experience in building lace braiders and the close and intimate relationship we enjoy with our customers.

Main drive

The driveline from motor leads directly to the main shaft by way of a robust toothed belt. A frequency inverter allows continuously variable drive speeds regarding the yarn quality and design.

Take-off

The Motor-driven take-off is synchronized with the main drive. A digital potentiometer allows variable speeds with guaranteed reproducibility.

Carrier drive system

This is a patented, further development and refinement of the familiar SKZ (Krenzler positive drive) configuration. An exact cam in the cylindrical bottom part of the coupling gear acts in conjunction with an actuating pin to determine the precise moment of driving disk activation. The actuating pin, located horizontally in the bottom part of the coupling fork, is mechanically fixed. As soon as the receives a signal from the design control, it releases the mechanical lock and the actuating pin. The pin engages the coupling gear cam and executes the timed half-turn of the driving disk. The principal benefit and improvement embodied by the new generation of machines is the immediacy of the response of the driving disk and carriers to the solenoid. Besides the main drive and beater eccentric, no moving parts at all are accommodated underneath the machine’s base plate. This ensures a very high reliability even at high working speeds of up to 280 rpm, substantially enhanced user and maintenance friendliness and a reduced spare part requirement. Every lace braiding machine is equipped with an automatic central lubrication to reduce the maintenance requirement. This device lubricates the top plate of the carrier track and beater to increase the availability.

|

|||||